Trolley Canal Boats (Excerpt)

Posted by Gail the Actuary on January 8, 2010 - 10:26am

This is a guest post by Kris De Decker. Readers will remember that Kris was the author of the Oil Drum post Wind Powered Factories. A longer version of this post on trolley canal boats was published in low tech magazine.

For many centuries, canal boats were propelled by men, horses or mules on the towpath beside the water. Before diesel power took over, engineers developed several interesting methods powered by electricity: trolleyboats, floating funiculars and electric mules. Many of these ecological solutions could be applied today instead of diesel engines. Because of the very low energy requirements, they could easily be powered by renewable energy, generated on the spot by water turbines located at sluices. One trolleyboat line is still in use.

Most of these systems are at least four times more efficient than diesel powered barges.

As described in a previous article, trolleybuses and trolleytrucks would make a lot of sense these days because they could deliver electric transport for a bargain, using simple and existing technology.

The same method was once applied to boats, too. Not for sea travel, of course, but for canal transport. Some canal boats were also propelled by systems that resemble those of cable trains, and yet another method combined common railway technology with canal barges.

All this happened at the turn of the twentieth century, mainly in France and to a lesser extent in Germany, in Belgium and (only experimentally) in the United States.

Up until the second half of the nineteenth century, canal barges were the main means of transporting goods over longer distances through regions where no good natural waterways existed. In all of Europe by the end of the 1800s, there were between 19,300 and 24,000 kilometres (12,000 and 15,000 miles) of canals. In the US in 1880, the total length of canals was around 7,200 kilometres (4,500 miles).

Mules and horses

From the 1840s onwards the rapid progress of railways threatened to make these canal networks obsolete. In 1880, already 3,200 km (2,000 miles) of canals in the US had fallen into disuse because of the rise of the railroads.

Canal boats, which had a capacity of up to 240 tons in the second half of the 19th century, were towed by horses or mules on the tow path (sails were not an option on most canals). This method was very efficient compared to non-motorised land-based transport; a horse could carry 10 times more cargo in this way than was possible when hauling a cart on the road. Compared to the new railways, however, the cargo capacity of animal powered barges was limited and the speed was low.

In most countries, animal traction remained the only method in use on the canals, until it was superseded by diesel engines in the 1930s or later, or until the canals fell into disrepair altogether (like in the United Kingdom). But, faced with the decline in traffic at the end of the 1800s, some governments and canal companies attracted engineers to look for more modern and efficient ways of boat propulsion to compete with the railways.

Steam barges

The obvious solution to canal barge transport was the steam engine - the same technology that kept trains going. Some canal barges were indeed converted to independent steam powered vehicles or towboats, but it soon became clear that this could not work when applied to large numbers of boats.

The reason was the state of the canals. In those times, canals were simply a large ditch without reinforced banks. If all barges would be equipped with steam engines onboard, or towed by steam boats, then the wash of the screws (or paddlewheels) would have destroyed the banks of the canals in no time.

Another obstacle was the limited depth of most canals, not exceeding 2 to 2.5 metres (6.5 to 8.5 feet) and this only in the middle of the canal. This made higher speeds problematic, because the stern of a propeller powered boat comes to lay deeper in the water as speed goes up.

A third problem of steam power was that the bulky engine took away cargo space, thereby lowering the efficiency of the transport system. This made that, even though steam boats already existed since the end of the 1700s, and many of them were in use on rivers and lakes, only 84 of them were operated on American canals in 1906.

Batteries

Because of these challenges, another obvious method - electric boats powered by batteries - was no solution either. At the end of the 19th century, thousands of electric automobiles were in use on the streets.

The first "automobile" or independent boat carrying its own battery was already demonstrated in 1838, and at the end of the 1870s one even made a trip across the English Channel. But, these boats were not suited for canal transportation. The propeller or paddlewheel would create the same wash as a steamboat, destroying the delicate canal banks. The batteries would take up almost all the cargo space.

Overview of electrical methods

Ultimately, engineers found the solution in electric propulsion without the use of batteries. Roughly, all methods can be divided in five classes:

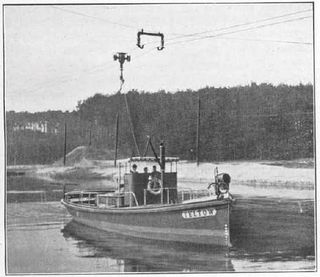

- Trolley propeller towing - engine on the boat.

- Trolley submerged chain towing - engine on the boat.

- Funiculars - engine on the banks.

- Manned electric mules - engine on the banks.

- Unmanned electric mules - engine on the banks or over the water.

Most of these systems were initially powered by steam engines, and later adapted to electricity, which made them much more efficient and practical. Some systems were afterwards converted to diesel engines. With the exception of funicular boats, all electrical systems were fed by a trolley line.

Apart from some regional success stories, none of these technologies found widespread use, in spite of the many successful tests. Peak oil and global warming were no concerns in those times. Most countries chose to further deepen out and reinforce their canals in order to allow self-propelled steam and, a bit later, diesel boats.

At the end of the article I will explain why it is time to ditch these and finally give the trolley systems the attention they deserve; they are our best chance to develop a completely oil independent, land-based cargo transport network with a large capacity.

The original article discusses all of these five methods. Here, we are providing only a bit of information about the method that found widespread use on a regional scale.

4. Motor locomotive haulage (electric mules)

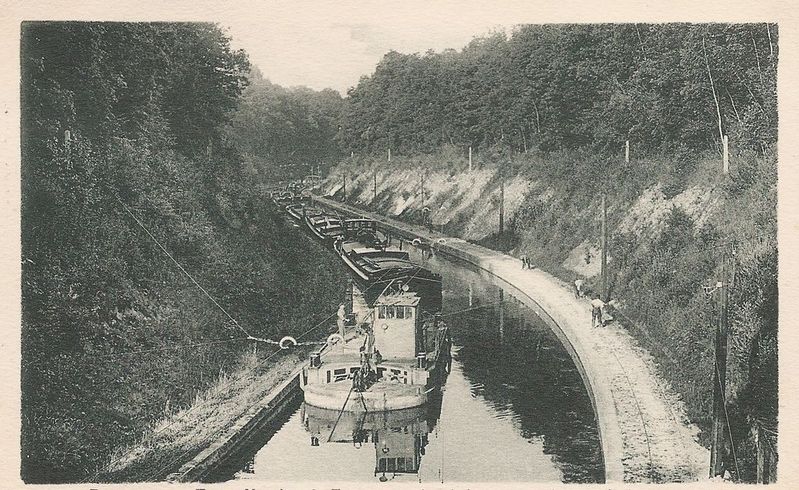

The only method that found a widespread use, at least on a regional scale, adhered to the old and primitive method of haulage or towing by mules on the path next to the canal. But, for the slow and uneconomical animal, a more efficient mechanical mule was substituted, hooked up to a trolleyline. The machines were either run upon a track on the banks of the canal - this method being practically a railway along the banks, the boats being trailers connected by a 50 metre (165 feet) long tow line to the motor cars (illustration below) - or either run upon the towpath itself - this method somewhat resembling a land-based trolleytruck convoy (picture above).

As with the animal powered systems, two persons were needed to operate the convoy: one on the banks (driving the locomotive or truck) and one on the boat (steering). Using this method none of the boats were equipped with a motor, which resulted in the same advantages as with the funicular [cable towing] system: any boat previously towed by mules or horses could be hauled in this way without any adaptations or the need for a specially designed towboat, and no wash was created, leaving the delicate canal banks untouched and eliminating the need for deeper waterways.

Electric mules on rails turned out to be much more reliable on the towpath than trolleytrucks, being operational every day and both day and night. The trolleytruck system only worked during daylight (at night too many drivers would end up in the water) and it could not be operated in winter conditions. The use and maintenance of the track system was two times cheaper than the trolleytruck system, but because of the higher capital costs a trolleytruck system remained a better choice on sections where traffic was low.

Bring back the trolleyboats!

All the above is more than a gallery of obsolete technology. Canal transport is already one of the most energy-efficient ways to transport goods. For every litre of fuel burned, a barge can carry a tonne of cargo for 127 kilometres (79 miles), compared to 97 km (60 miles) for a train and 50 km (31 miles) for a truck (source). Electrifying canals could boost this efficiency even further, bringing the possibility of a zero-emission transport system within reach.

These days many canals have reinforced banks, so trolley systems with a propeller would no longer pose a problem. However, especially interesting are those systems in which traction happens on land instead of in the water (all systems excluding a propeller), because they are extremely energy-efficient.

To move a barge of a certain tonnage at low speeds, an electric mule (or any of the other systems described) needs an engine at least 4 times less powerful than when this engine would be placed on the boat itself, propelling a screw (source). Wheels are more efficient than propellers. This means that for every litre of fuel, a barge towed by a machine on the banks or via a chain on the bottom of the canal could carry a tonne of cargo for 500 kilometres (310 miles) - ten times more efficient than a truck or lorry.

Zero-emissions transport system

Because many canals have locks and thus artificial height differences between water surfaces, renewable energy could be generated on the spot. The required electricity to power the barges could also be generated by wind turbines or solar panels, which would make a zero-emissions transport system also possible in flat countries. Because of the very low energy requirements, the investment in renewable energy would be relatively small (contrary to, for instance, the plans to charge electric cars using solar panels). And as always, obsolete systems can be substantially improved with today's technology and materials.

Low-tech canals

Of course, canal barges are much slower than trucks or trains. But, if they could haul cargo for almost nothing, it would still be an economical choice for many goods. This advantage would grow if oil prices would rise. Many abandoned canals could be put in use again, and even new ones could be built.

Almost all methods above were designed for use on very shallow, trapezoidal "low-tech" canals, which were only 2 metres (6.5 feet) deep at the centre, and much less on the sides (see picture below). These are not public works like the Panama Canal which would take decades and require thousands of workers (or energy-guzzling machines) to build. This is something that might even be done on a community level.

Sources (in chronological order):

"Halage funiculaire", La Nature, December 15, 1888

"Gov. Flower's trolley plan: he would equip the Erie Canal with electricity", The New York Times, June 10, 1893

"Electrical boats and navigation", Martin Thomas Commerford, 1894 (this book has many more technical details on the methods used).

"Electricity on the canals; another scheme for utilizing the trolley system", The New York Times, January 21, 1894 (electric mules)

"Traction mécanique des bateaux sur les canaux", Mémoires et compte rendu des travaux de la Société des Ingenieurs Civils, January 18, 1895

"Trolleyline for Canalboats: contract signed for an experimental system of four miles - how it would be operated", The New York Times, July 26, 1895

"Electricity on the Erie Canal", The New York Times, September 28, 1895

"The Canal Trolley works well: successful test of the new system of propulsion", The New York Times, October 27, 1895

"Boats run by electricity, how the Lamb system has been found to work on the Erie", The New York Times, November 24, 1895

"Der Elektrische Schiffzug", Georg Meyer, 1906

"History of the canal system of the state of New York", Nobel E. Whitford, 1906

"Canals and other inland waters", US Census Bureau, 1907 or 1908 (pdf)

"La traction électrique des bataux sur les canaux", Mémoires et compte rendu des travaux de la Société des Ingenieurs Civils, November 1908 (lots of technical details here also, but in French).

"Un neuvo systema de sirga funicular electrico para barcos", M.Ed.Imbeaux, 1914 (pdf)

"Le canal de Bourgogne et son traffic", A. Desaunais, 1928

"Electric mule could propel a canal boat system", the US GenWeb project, July 29, 2004

"The canals of England and Wales and their history", Jeanette Briggs, 2008.

"Traction mécanique sur les voies navigables", G. de Frontenay (website - many pictures here)

"Le tunnel de Mauvages", bordabord.org (many pictures)

"The Erie Canal" (website).

wow,wow and WOW, what a score on information and tried ideas.

way cool.

A few comments about canal transportation:

-If you've got an economy with lots of unemployed people needing work, canals are a relatively low-tech, labor-intensive transportation infrastructure to build. They were being built by many societies in pre-industrial times, so it should be possible to build and maintain these even in a post-industrial, post-carbon world.

-Canals are scalable. You can start with one canal connecting different neighborhoods within a single city, then add more, then start building canals between two cities, etc. There really is no minimum "critical mass" that must be in place before canals become viable. Economic viability is really more a matter of what competing modes are available, and at what cost.

-Canals are sustainable. They do require some ongoing maintenance, but this is not an insurmountable burden. Keep them properly maintained, and they can stay in operation indefinitely.

- The electric motive power options discussed here are interesting, and certainly preferable if possible. However, there are alternatives available (animals, people) to haul the barges should society be unable to maintain the level of technology and industry necessary to maintain the electric power systems. There are few, if any, other transport sytems that are as well positioned wrt having fallback systems, which thus suggests that canals are a particularly resillient transport system, and can contribute a great deal of resillience to an economy at large.

I recently saw a map of the central european canal system and natural waterways. I was impressed. There is a huge infrastructure that connects all the main industrial centers and cities of the continent, from the baltic sea to the black sea, from the atlantic to the mediterranean.

Many of the UK canals have extremely limited capacity especially at locks. Canal boats are called narrow boats for a reason. Many are only 6 feet wide. It would be very expensive to rebuild the locks on out canals to increase capacity.

Also, as water is lost every time a lock is used, the supply of water to replace the water lost downhill each time a lock is used limits the throughput capacity, particularly in low rain seasons. Of course, the water could be saved by pumping into side ponds, but that takes a lot of energy.

Canals were out-competed on speed and capacity in the 19th century by the steam train.

In flat terrain this is less of an issue.

The UK is a special case here since (as with our railways) the UK canal system was an early development so in most other countries the locks (like the rail loading gauge) are larger than here. There are several alternatives to locks that might be better on a reinvented system, wheeled boats with railed inclined planes being one option that saves water waste.

The main point above though may be better expressed by asking - 'is there a critical speed below which a canal can offer lower energy transport than rail?' I'm not sure that there is such a speed, some 19th century data on what a horse can haul on rails vs a canal would answer this.

The other problem is that a canal is more than a simple ditch - a lot of effort is required to keep the water from leaking in all but the most favorable conditions and much early railway (or more properly tramway) development was driven by the need to communicate across territory where canals could not go.

I would think the type of system proposed could have a place in a more sensible transport system than now but within a limited range of suitable conditions (say where canals for a natural extension to coastal shipping or where most of the infrastructure is in place for drainage).

Another option was at foxton locks

http://en.wikipedia.org/wiki/Foxton_Locks

which used an inclined plane - an elevator for boats.

http://en.wikipedia.org/wiki/Canal_inclined_plane

Because the lift is exactly counterweighted even when loaded because of archimedie's )(sp!) principal, only frictional forces

need to be overcome.

This saves most of the water lost in the lock staircase.

The rubber baron in the Werner Herzog film Fitzcarraldo did it the hard way - just heave a 320 ton steamer over a hill by brute force.

http://en.wikipedia.org/wiki/Fitzcarraldo

Maybe someone should have told him about balancing counterweights and that sort of thing.

The Wikipedia page suggests the design mistake which made the Foxton Inclined Plane uneconomic:

Given the rather small energy requirements of the inclined plane, a hydro turbine driving a generator to power an electric motor would have been superior. There would have been no need to fuel a boiler, the turbine could be left dry when no power was required, and the water consumption of the turbine would still have been a small fraction of what conventional locks used.

How different things might be today had that one mistake not been made.

I'm a believer myself when it comes to canals.

But the authors of this fine piece commit the usual sin of failing to discuss the downsides.

One is ice-It seems likely that canals in northern areas will be out of service due to ice for weeks or months every year, although it might be possible at some considerable expense to leep them open.

The other biggie is water. It takes a lot to keep canals full , especially when locks are needed.Furthermore the soil is highly permeable in many areas , and the water will simply disappear into the soil in huge quantities. Evaporation and the (hopefully ) localized accumulation of dissolved salts in the canal water may become a significant problem.

It should be possible to line canals that will recieve heavy use with clay or synthetic materials so that they don't leak too much, and this would also solve the salts problem.

I agree that electricity used in conjunction with some sort of on shore traction system is the way to go.Moving chains or cables mounted high up on poles are good because they take little ground space and require little extra excavation which would be a huge plus when building thru hilly areas.Snow drifts would not be a problem either.

But my guess is that an "electric mule" on a railroad track is best in most cases-any given mule that fails can be quickly replaced with a spare.Some diesel powered units, or some dual powered units could be kept in use or on standby in case of power failures.In the last extremity they could be replaced with simple wood burners ala the early locomotives.

The slow speed of canal transport might in the end prove to be a disguised blessing.Cities and communities would necessarily have to plan ahead and maintain adequate stocks of coal, non perishable staple foods, etc.Currently with just in time delivery we would be royally screwed if anything goes seriously wrong.

Off topic from here-but does anybody know of any potential new technology that could make good use of the waste heat generated by say a stationary diesel engine other than combined heat and power using the heat for water and space heating??

It seems to me that the high temperature exhaust should be usuable to drive some sort of small scale chemical manufacturing process for instance.

Maybe connect a stirling motor and generate more electricity? Or distil some alcohol that you could add to the engine's fuel? (can one mix diesel with some alcohol?)

Yes, downsides I also thought about while reading;

1. Water: May be in short supply in the future in many areas.

2. Speed: Passenger travel would be too slow, except for 'cruise' type travel. Freight could only be non-perishable in anything other than local movement.

3. Carrying capacity: much larger populations may overwhelm the capacity of older canal systems.

4. New canals would need to pass the EROEI filter.

This could be a complement to rail in areas that have existing (or extant) canal systems.

The C&O canal that went into Washington DC went bankrupt not long after the rail line was finished.

C&O canal had competition from B&O railroad almost from the beginning (1830s). It stayed in operation until WWI IIRC, the thing that did it in was huge expense of repairs following periodic floods on the Potomac river.

The C&O Canal reached Cumberland in 1850, and the company went through bankruptcy proceedings in 1889.

And even when it reached Cumberland, the railroad had already taken over passenger and light freight, leaving the canal with little but coal transport as its market.

http://www.whilbr.org/itemdetail.aspx?idEntry=6016

Oldfarmermac, Probably the most underutilized use for waste heat is cooling. Absorption refrigeration, primarily using ammonia, has been around since the mid 1800's and is still a very viable use of mid to low temp waste heat. This would allow a community to keep their food which had always been a severe challenge pre fossil fuels. Another use, of course, is the drying of foodstocks, or anything else requiring the removal of water from a manufacturing standpoint, and is even something that could be done with the remaining waste heat after the cooling process is accomplished. Refrigeration by absorption or adsorption still require heat to be removed by some sort of heat exchanger. Bill

Thanks Treeman.

I have had some minor contact with this technology-a refrigerator that cools by burning bottled gas.

Do you know of a web site that goes into it in some detail on a basis comprehensible to those of us without engineering degrees?

I do have a couple of years of the basic sciences at university level but I have long since forgotten what math I learned above the level of algebra.

It seems that if it can be commercialized again that it might work well in conjunction with biomass plants producing electricity for instance.

If the electricity and transportation are available I foresee industrial scale agricultural production followed by industrial scale drying, freezing , and canning continueing far into the future.

Here's a basic explanation, and here's another one with a little more detail. If you are looking for calculations, that will fall into the engineering realm you were hoping to avoid.

See this lecture, or this Absorption Chiller Guidelines.

I'd expect localized (community, residences) scale canning, dehydrating (etc) as well.

Most RV refrigerators are absorption, run off of propane (Norcold, Dometic). Quite efficient and last for years. Almost no moving parts. There are residential versions as well. Many off-grid folks use these. An old Navy ship I seved on TAD still had large walk-in ammonia/absorption freezers that had been in service for 40+ years. The ammonia is a hazard if it ever leaks.

The downside of absorption refrigerators is rather low thermal efficiency; the "boiler" (where heat is used to separate ammonia from water) is at a fairly low temperature and the entropy increase from flame to the boiler is enormous. From the docs I have, the coefficient of performance (cooling vs. heat input) peaks out at about 0.5. I suspect that a back-to-back Stirling engine driving a Stirling chiller would have potential for much higher efficiency.

How about making medium-pressure steam to supply additional power, and using the exhaust steam to run either a distillation system or process heat requirements for biodiesel? If you fill the engine cooling jacket with oil instead of water, you can run it hot enough to generate low-pressure steam.

Greenhouse heating - plants love heat!

ofm:

RE: Wintertime ice. THis is only a "problem" for a society that is premised on operating 24/7/365 with no adjustment for seasonal rhythms.

In the old days, farmers looked forward to the winter snowfals. As soon as the first heavy snowfall came, very large, heavy rollers would be hitched to a team of sturdy draft horses, and all the roads would be packed down. This would continue all winter. Meanwhile, the farmers would hitch up their teams to sleds and sleighs. Wintertime was the time when heavy loads would be hauled from the farm into town - and to warehouses alongside the railroads or canals - and when heavy loads would be hauled from the town warehouses back to the farms. It was so VERY MUCH easier to slide those heavy loads along the icy roads than it would have been to haul them in a waggon. Indeed, try to haul too heavy a load by waggon, and you ran a serious risk of either busting a wheel or axle, or getting bogged down in the mud. Hauling over ice and snow, on the other hand, was a piece of cake.

Goods for shipment to the distant cities (and this included not just grains and timber, but also ice - a very, very big business back then) would accumulate in the warehouses besides the canals over the winter. Come the spring thaw, and they would start shipping them by barge to the cities, which would continue until next winter's freeze.

When you look at all of it as a whole system, and adjust activity patterns to seasonal rhythms, there is no reason why canal transport cannot work quite well.

"Wintertime ice. THis is only a "problem" for a society that is premised on operating 24/7/365 with no adjustment for seasonal rhythms."

An excellent point that can't be repeated enough. We have to decide what parts of BAU we are trying to replicate and at what price for what (and for whose) benefit.

It's a point I usually make in reverence to concerns about intermittency of wind and solar--why shouldn't some activity slow down or stop sometimes in response to natural events.

We recently had a blizzard here in the midwest and hundreds of miles of interstate were closed down. Presumably we could invest billions of dollars to completely enclose the interstates so that they would never shut down because of weather. But everyone recognizes that this is not a reasonable price to pay for the rare privilege of being able to thumb our noses at these occasional, extreme whether events.

If we bow to natural variability here, why not in other areas?

In the past winter was a time for cutting ice. London imported enormous quantities from Norway (and even the USA). It was carried by ship and canal and stored for summer use.

London's Canal Museum behind Kings Cross station is in a canal-side ice storage warehouse built in the 1860s for an ice cream company.

http://www.canalmuseum.org.uk/

The book 'The Frozen Water Trade' by Gavin Weightman is a good read. This describes the bizarre 19th Century attempts to export ice from the Hudson River to the Caribbean and even to India.

The idea of having ice in drinks seems to have been a desperate marketing ploy from this period.

If you haven't learned how to use e.g. ammonia absorption (easily done piecemeal with two tanks connected by a pipe with a valve in it, charged with ammonium hydroxide in one tank), shipping ice in barges and ships may have value. Not so much now. This is one thing where knowledge replaces lots and lots of capital and labor.

The canal I live on never freezes over even though we have seen temperatures drop to -10C in the last couple of weeks and last year it dropped to -18C. They control the flow rates on the canal with a water sluis gate. I guess we would eventualy freeze over if the temperature was cold for a prolonged time but then so would the rivers.

Odd that PV powered electric barges are not considered. I would have thought a 1 kW panel would be plenty under most daylight.

Wouldn't they need a propellor? If so, they would need deeper canals, and reinforced sides, requiring quite a bit more energy in construction, it would seem like.

Gail, These things don't need to pull water skiers down the canals. If a shallow prop were placed forward between pontoons the result would be relatively little turbulance absorbed by the pontoons and a very small wake An alternative is the type of very efficient flipper type drive found on some brands of kayaks. Topography would seem to be a bigger problem but I like the idea of wheels mounted that would allow a rail system to get over obstacles. Maybe one barge pulling another up the hill while it is going down.

PV powered electric barges were not considered because the article gives an overview of late 19th and early 20th century systems. Solar panels did not exist yet.

As Gail notes, they would need a propellor and thus deeper canals, and I guess they would also need batteries? These would take away cargo space and add weight.

Moreover, I think you would need quite some solar panels, which might pose a problem for loading and unloading. See for instance the pictures of the Dutch Open Solar Boat Challenge: http://www.dutchopensolarboatchallenge.org

It seems like you definitely would need batteries. You have a number of problems: cloudy days; night time, and trees casting shade over the canal. The combination of these things might lead to a fairly low percentage of capacity actually being used.

External propellers aren't a requirement. Impellers or water jets can be used, or internally ducted propellers. Oyster boats have outboards mounted internally (in a sort of tunnel hull) that allows them to turn a tight radius and prevents prop damage. Very shallow draft.

Military landing craft have jets. Barges don't need speed, just slow and steady. Standardizing the barges would make the system more efficient. Traction systems like they use for theme park water rides could be used if all barges were similar.

There's no need to re-invent the wheel here. Just apply what we've learned about efficiency to an ancient technology.

But the large slow turning prop is the most efficient design, except obviously for a traction system. That's why they're popular in steam launches where economy is dear because the amount of space your powerplant occupies and in electric launches where you have the additional burden of batteries.

1kW is one horsepower or less after considering the efficiency of the motor. Doesn't seem like quite enough (see the seven mules in one of the pictures). However if a few more kW of solar were placed along the canal somewhere, that could probably power an electric mule like those mentioned in the article. That might allow storage for hydro to be built up during the day and used at night.

Good point, there could be such panels all along the canal. There could be other supplies at various points along the canal that could be employed when useful--it sails that sails weren't often useful, but if the barges were made sail ready, they could pick up one along the way when the wind was favorable, without having to lug it around all the time.

Could flows in the canal be managed so that you had flow in the desired direction and then you could reverse it for traffic the other direction?

I'm thinking of a reservoir at a higher altitude than the canal on either end at at crucial points along the way that could be allowed to fill then be drawn down when the required flow was needed. They could even be filled by pumping water with wind mills from lower-altitude reservoirs, lakes or streams.

Mostly, though, we have to stop trying to move so much stuff, and instead move people to live in places where resources are available, then make sure they are living lifestyles that are largely or completely supportable by these local sources.

This is one of my recurring retirement fantasies : buy a canal boat and fit it out with an electric motor, batteries and solar panels. Back of the envelope calculations indicate that a couple of kW of generating capacity should be enough to putter around the canals of Europe, heading south for the winter etc... just as many people already do on diesel powered boats.

I would anticipate that this will be highly feasible in 15 years time, with cheaper more efficient PV, indeed I wouldn't be surprised if there were a gradual switchover to electric, of the existing tourism and lifestyle canal boats. Already, the open runabouts you can rent in touristy canal sites are battery electric.

This would all be spoiled, of course, if the extensive European network of narrow shallow canals were to see a resurgence of commercial traffic, but I find this somewhat unlikely. No doubt a certain number will be upgraded to the gauge required for freight on the existing major waterways, but I'd be surprised if the majority of the vast network were rehabilitated in the next couple of decades.

The Panama Canal has used electric "mules" for over a century. The new locks (for the "Super Panamax" tankers) are designed to use diesel tugs instead. Seems like a step backward to me:

http://www.thepanamanews.com/pn/v_13/issue_23/business_04.html

Those trolley boats are only intended to maneuver the freighters into the locks. Ships always cross the Panama Canal with their own engines. Anyway, it's a bit comparing oranges to apples, inland channels are constructed for much smaller boats than container ships.

It seems to me just a difference in scale. Most canals are designed to move cargo and people, regardless of size. I was just pointing out that they chose diesel tugs instead of the "tried and true" electric mules for their new locks.

BTW, I've been through the Panama twice, Suez three times. Amazing experience. I was on a Navy ship in the Suez when they shot Anwar Sadat. The Captain took us to general quarters. The Egyptians held all ships in Port Said for a while until things cooled down.

It seems to me that the water flowing through canal systems could utilize high-volume, low-head turbines to recover some energy. EROI may not be worth it though. Solar and wind could be used to pump water back upstream as well.

On the Current River in South Central Missouri is a place called "Akers Ferry". This is a trolley propelled ferry that is still operational (though infrequent) today. Looks to be from early 1900's.

Great post, one caveat though, with water in as much demand as oil new canals might be hard to keep full.

How would be the EROI of a channel system compared to a low speed solar driven railway? The latter one would probably be better off in dry and sunny areas.

I think you mean efficiency (e.g. ton-miles per kwh), not EROI. (Neither a canal nor a railway "returns" energy...) As Kris said in the article, water transportation generally operates more efficiently than railways, so as far as that goes the canal would win. Which is to say, in flat areas with enough water, canals will win.

It is certainly true that in many areas there would be prohibitive costs that would preclude building canals in the first place. Not just dry areas but also mountainous areas. It is probably safe to say that we will never have a canal system across Arizona and New Mexico. Certainly in those two states a solar powered railway would be more economical.

Thanks! Here is a picture of it:

http://static.panoramio.com/photos/original/422407.jpg

I had an idea for an electric pontoon paddlewheel boat for rivers. Very wide flat pontoons for load carrying and maneuverability. When tied up the current charges between the pontoons (front could be hydraulically expanded to funnel water increasing flow) contacting the paddlewheel and becoming a generator. If batteries become charged excess energy could go back into the community system where tied up to.

I've considered building one of these:

http://www.buffalosolarboats.com/new_e_boats.html

I like your idea of using the water's current to drive the motor as a generator. Seems to me that many of these small canal boats could be made solar/plug-in electric.

I suspect that if bau continues to lurch along we will see some major gravity powered water transfer projects built out over the next few decades-a river will be diverted from someplace with plenty of rain and at a higher elevation to lower elevation dry areas.

A lot of the diversion might be best accomplished with large diameter pipe , as this would enable crossing hills without tunneling or pumping, but long stretches might be buildable as dual use /canal / water transport .

In this case timber, coal, grian, and other bilk products might go to market almost fuel free.

The rivers once served this way and still do to some extent.

The two stroke diesel engine used in large ships is the most efficient prime mover (up to 52%). Diesels used in canal barges are probably as efficient as grid electricity.

The length of canals is orders of magnitude below railroads, which are an order of magnitude below roads, therefore, their electrification is a low priority item for saving petroleum products. Also, in the US most of the inland waterways are major rivers that are too wide for overhead power without putting navigation hazards in the waterways. And the cost would be prohibitive.

Railroads are limited by terrain and part of their efficiency is due to the fact that the grades are kept low. On a new factory project I did in Mexico the RR specified the maximum grade be 2%, which required extensive earthwork.

Canals locations are much more restricted than railways because they have difficulty handling any change in elevation. They tend to be along existing waterways and not necessarily where freight needs to go.

High value traffic in the US rarely moves by barge due to the low speed. Barges handle bulk materials like stone, sand and gravel, grains and coal.

I fully support inland waterways and think they should be high priority infrastructure spending projects. I'm glad that they are finally receiving some long over due funding. If the waterways got the necessary funding for badly needed maintenance and upgrades they would be more widely used.

Efficiency wise the relative energy requirements for transportation modes are:

Pipelines: 1, water transport: 2, rail: 3, road: 10, air: 100.

(Source: The Encyclopedia of the History of Technology, p 516)

Share of petroleum use in 2000: Cars: 40.7%, trucks 12.7%, passenger air: 6.7%, waterborne freight: 2.5%, rail freight: 1.2%, air freight: 1.1% (Source: BP)

Now we're talkin' reality. If you get the chance watch a movie with Henry Fonda called " A farmer takes a wife."

http://www.imdb.com/title/tt0045752/

The movie takes place on the Erie canal and covers the transition to rail. I thik this would be a fun project and a great job of the future.

Paul has a point. It is likely rail is much more efficient than canals at anything smaller than a 100 car train, especially if we use 0% canal routes and slowed the cars to a crawl to make the comparison fair.

Brand new, perfectly good canals were abandoned practically overnight when rail came in (at least in the U.S.) I think the killer was high maintenance. I suppose canal tech. has improved, but so has rail.

Can anyone think of specific place where new small canals would make sense? I hate to say it, but I think it would be cheaper to fill in abandoned canals and make them into rail routes. I prefer canals over trains in my heart, but I think Alan and Totenilla win this round.

Cold Camel

Trains actually get more efficient the longer they are. If trains are shorter, they will be less efficient. So that part you have backwards.

Kris and Paul both agree that water transport operates more efficiently than rail, so you have that part backwards as well.

It is true that rail has speed advantages, and that it can much more easily go places that canals can't. This is somewhat the same as being more efficient, but not exactly. It simply means that if you have enough energy available, building a railroad makes sense. If you have less energy, that's not necessarily so.

It seems to me than in many if not most cases, it would be folly to do this instead of building a parallel rail route. Either way you'll need to move earth, so why not end up with two birds instead of one?

The article made me think of Greer's "The Ecotechnic Future", a canal could be a huge asset after the scarcity industrial and salvage societies.

I wonder how rail and canal compare resource wise?

I also wonder if canals are higher maintenance.

A railroad uses a lot of steel and wood, and in terms of a resource canals contain water and plants and animals...

Anyone seen the floating markets in Thailand? I think if we looked at rail and canal in terms of total outputs canal would be more preferable, although not in every instance or location

Urban Canals in New Orleans

Basin Street (the birthplace of Jazz) was located where the first canal turning basin was filled in. A half block from the French Quarter.

Canal Street is a very wide street that was reserved for a canal (to be conveniently dug between the French and the Americans).

I-10 was located on the southern 2/3rds of the second major canal to the CBD/FQ. Dug by Irishmen (a renewable resource) because slaves were too valuable. No one counted, but at least 10,000 died, perhaps 20 or 25,000.

These canals were used to transport food, wood, etc. from the shores of Lake Pontchartrain to the city. Also used to escape the summer epidemics by summering on the much healthier (and slightly cooler) North Shore.

Alan

Of course, people used to locate themselves along waterways because it made it easier to send and receive freight. Because it's development preceded fossil fuels to a greater degree, Europe has the advantage over the US that it's population centers are usually located on major waterways. The US will probably need to restructure in that direction to some degree. (To put it another way, people who live in Phoenix may find it advantageous to move back to Buffalo, despite the cold winters, rather than the other way around that has been the trend.)

Before railroads transportation over dirt roads was prohibitively expensive, railroads costing something less than 1.5% as much per ton mile as horse and wagon over a dirt road.

A horse could haul a 3 ton load by wagon or a 30 ton barge.

We can’t go back to canals because we still need to get crops, and lumber from where they are grown to markets and we need roads and railroads for that. Besides, the waterways would get so congested nothing could move except on major rivers and along the coasts.

What is needed is a more efficient way to move people like we did with electric street railways 100 years ago. Street railways also moved freight around cities.

Agreed Alan. While there is a certain romance to canal systems, from a purely practical standpoint it would be more efficient to convert many of these corridors to electric rail, IMO.

Paul:

See my response to OFM above. The really heavy loads were hauled between farm and town in the wintertime, over the ice and snow on runners rather than wheels, as I explain above. There would have been a great many warehouses in towns along canals to store goods over the winter for shipment after spring thaw (or to store manufactured goods that had been shipped in before winter to be sold to the local community). Heavy loads were only hauled (or maybe more accurately, attempted to be hauled) on waggons in areas which did not get much snowfall, or by people who for one reason or another just couldn't wait until winter.

"We can’t go back to canals because..."

There's no reason that canals can't be part of a package of more efficient transportation, along with railroads. I think most of the world's canals have never been abandoned? Maybe I'm wrong about that but it would interesting to know.

Yes, we could go back to canals; the question is, under what circumstances would we want to?

Given that rail is superior in almost every way (can be placed on the surface, moves much faster, can have grades up to 1-2%, can have grade crossings for roads), we'd probably be better off with rail except where canals already exist. I've ridden and skated parts of the Erie Canal towpath and it's pretty neat, but trolley-car rails on every other street would be a lot better than one canal that comes somewhere near town.

Between 5 and 10 freightships come through the lock opposite us everyday even though the city here is a rail hub.

Paul,

From one Paul an engineer to another, I think your dataset here "Pipelines: 1, water transport: 2, rail: 3, road: 10, air: 100.

(Source: The Encyclopedia of the History of Technology, p 516", and that used for the original article, is not strictly applicable to this situation, for two reasons.

Firstly, the energy efficiency of water transport is scale dependent - very large ships are much more efficient, in energy per ton-mile, than small ones at the same speeds, or equally efficient at faster speeds. Canal barges often have flat bottoms, which are not as hydrodynamically efficient as the rounded hull of an ocean going ship. And, the barges are operating in shallow water, which increases drag in the water (ask an Olympic swimmer about swimming in shallow pools) Long barge trains will lessen the length penalty, but you still have flat bottoms and shallow water.

Secondly, the rail figures are averaged for all rail transport. If you could split out the average for transport on flat ground, it would be lower. Trains average about 40mph -if you slow the trains down to canal speed, with no air resistance, it would be lower still. Since we are talking about building new canal side rails, and the engine is running at canal speed, you might as well just put the cars on the rail behind it. If you are going up a gradient, then the energy efficiency, (and time efficiency) of barges through locks get worse still, assuming the lock water could otherwise be used for hydro power as has been suggested. And long, efficient barge trains present their own problems going through locks, as the train must be separated and re-connected

The best data set I can find is the Transportation Energy Databook, 22nd Edition, 2002, by Diegel and Davis, of the Oak Ridge National Laboratory (found this on Google Books).

Table 2.15 give freight transport energy intensity for road, rail and "domestic waterborne commerce". This has been compiled by the US Army Corps of engineers, and may still be dominated by larger ships for coastal shipping, but I think it is the most accurate number available. Their numbers for rail are 352btu/ton mile in 2000 (down from 700btu/ton-mile in 1970) and waterborne freight fluctuates each year, but is rarely below 350, and looks to average about 380 btu/ton mile. So, with smaller barges/ships, not ocean tankers, your energy efficiency is on a par with rail. Slow the trains down to barge speed, and on flat ground, and they will use less energy still. The energy source for either can be diesel, or electric, or solar assisted so no advantage there.

Another aspect not discussed here is the capacity of the canal, in terms of freight per day per "lane". Since we are operating at canal speed of 4mph or so, compared to 40mph for trains, you need to run ten times as many barges per day for the same freight capacity. Assuming a canal and rail line packed full of barges/rail cars, the rail line can move ten times the freight per day as the canal. For a wide canal with two way traffic, you need two rail lines to match, but the numbers are the same. So for the investment in the canal, you can only move 1/10th the freight per day of a rail line, and at one tenth the speed.

If you compare a canal business to a railroad along the same route, the canal operator has one tenth the freight capacity per day, and each unit moves at a tenth the speed, ergo, you can't charge as much per unit freight (maybe half) and you only get one tenth the tolls per day, so your revenue is limited to about 1/20 th of the parallel railroad. Even if your operation is more energy efficient, it would only be marginally so, and it would almost certainly not be profitable if you have to pay your share of canal maintenance, and property taxes like the railroads do.

And the cost of building and maintaining a railroad must be cheaper than building and maintaing a railroad plus a canal. You have got a greater investment for a system with a tenth the capacity. Better to just build and operate the railroad, and use the capital cost saved to go and electrify another railroad somewhere. There may be some specific cases where the deck is stacked in favour of canals, such as downstream (only) transport of logs or, where the canal already runs point to point, etc, and I'll bet those are the places where canals are still maintained and used today.

Overall, a nice idea, and worthy of consideration, but upon close consideration modern data, the numbers just don't stack up. Except for some specific cases, our resources are better allocated to expand and electrify the railroads.

+ 1

Paul,

Not disagreeing with what you are saying and the clarifications are appreciated.

In the US the major waterways are the Mississippi and Ohio rivers and the Great Lakes. The Mississippi River at New Orleans is a mile wide and over 200 feet deep. The barge trains huge and move at much higher speeds than on the small canals.

The US Army Corps of Engineers has energy efficiency posted on one of their sites.

See: Waterways: The Most Efficient Mode of Freight Transportation

http://www.mvr.usace.army.mil/Brochures/InlandWaterwayNavigation.asp

Also see the Efficiency section on the Wiki article:

http://en.wikipedia.org/wiki/Inland_waterways_of_the_United_States

Such tows are an extremely efficient mode of transportation, moving about 22,500 tons of cargo as a single unit. A single 15-barge tow is equivalent to about 225 railroad cars or 870 tractor-trailer trucks. If the cargo transported on the inland waterways each year had to be moved by another mode, it would take an additional 6.3 million rail cars or 25.2 million trucks to carry the load.

The ability to move more cargo per shipment makes barge transport both fuel efficient and environmentally advantageous. On average, a gallon of fuel allows one ton of cargo to be shipped 59 miles by truck, 202 miles by railway, and 514 miles by barge (95 km, 325 km, and 827 km, respectively).

Some elaboration

Circuitry

The variance from a straight line from Point A to Point B. Almost zero for air. In assessing rail vs. trucks for long haul intercity a 5% circuitry penalty is often assessed on rail (rail avoids inclines that trucks accept)#.

Water has quite high circuitry on some rivers (Lower Mississippi bends can almost double miles over a straight line between St. Louis & New Orleans). OTOH, another very heavily used waterway is the Gulf Inter-Coastal Canal (the Atlantic one is little used but Gulf ICC volumes compete with the Great Lakes). New Orleans to Houston is almost a straight line by barge.

The energy efficiency of rail varies, it is not a single number. For general cargo, double stack containers (from slightly vague memory) are about 40% for efficient/container than single stack containers on trains of the same length. Longer trains are more efficient, trains that do not brake are more efficient (rail over rail grade separation as well as road/rail grade separation), slower trains are more efficient (coal trains rarely go over 50 mph).

I looked at barge transport and I see it as an important niche mode. In comparing rail vs. barge, one also needs to consider that rail fits into a much broader network (and trucks fit into an even larger one).

Best Hopes for Energy Efficient Transportation,

Alan

# The Swiss are spending 15 billion Swiss francs (now = US$15 billion) on building a flat, almost straight rail link between Zurich & Milan vs a curvy road that climbs over the Alps for trucks.

Cajon Pass in California could use something similar. Some other places as well.

Paul,

I guess the real answer is, "they are more efficient than rail, only when they are more efficient". And clearly there are some such situations. Iand I'll guess they are where there are few or no locks involved.

But if we are doing a tow from a shoreline, a large canal is not necessary, we are effectively limited to two lanes. once you are out in the middle, you need self propelled or tug-towed barges. They are still efficient, for sure.

My main point ism that two build a new canal + a rail line on each side is more money, for less capacity, and marginal efficiency gain, compared to rail. If the canals are already there, i.e. they are "free", then it's a different story. A niche solution, but not a large scale one.

I would have liked to have seen the original author look for the sort of data you and I have found.

Sorry, Paul, the original article was already too long to be published entirely on TOD... There is so much to tell about canals, it is impossible to do it in just one blog post. I mainly concentrated on all these fantastic obsolete technologies that I discovered (to my great surprise, by the way). There was not much space left to discuss their future potential, or to answer the question whether or not canals are more efficient than rail (not an easy answer, as the discussion above shows). I will certainly take up the subject again for a future article and the information above will be of great help for that.

Probably a stupid question, but I have always wondered...

When you pull a boat from one shore, how do you prevent the boat from tracking towards the puller's shore and possibly damaging the bank?

Don't know for sure. But if you take a rope that is long enough, the force that pulls the boat sidewards will be reduced. The rest should be done by steering.

As far as I understand, this was accomplished by the bargeman slightly steering the boat away from the bank.

Thanks. I thought the speed of a horse/mule would have been too low for a rudder to be effective. Maybe I'm wrong.

I think the solution is just that you use a bigger rudder.

You might like Canal Boy, a book of historical fiction. Centers on the building and early operation of the Erie Canal. Alot of history, describing the theft of the cement "recipe" from Europe, selection of oxen, mules, horses, an ingenious machine to pull huge old stumps in the wilderness, etc. Well researched, a fun read, and a bargain at Amazon.

http://www.amazon.com/Canal-Boy-J-F-McGlinchy/dp/0595441882/ref=sr_1_6?i...

Interesting post and photos. Until the fossil fuel situation evolves more drastically I think electrified canals will remain in the realm of the giant cargo Zeppelin - seductive but out of reach.

The Rideau Canal in Ottawa, Canada's fine capital city, is an example of a 100+ mile 19th century military/commercial canal now given over to recreation and tourism purposes. In the winter you can skate on it for several kilometers. It isn't unusual to see sometimes highly placed civil servants in trench coats with briefcases or cell phones in hand gliding to work.

http://www.youtube.com/watch?v=AmIEzfPYxrc&feature=related

Never come across any stats on how many folks make it a part of their commute but anecdotal observation says there's quite a few. Every so often the TV news will interview people skating into town who swear it is the nicest part of their day. Skating has got to be a pretty efficient way to move a human body. I imagine it must compare reasonably well to cycling in regard to calories burned per hour per kilometer?

If a canal froze solid in winter wouldn't electric mules be able to pull vessels mounted on runners? Wouldn't that actually be more efficient than pulling them through water because there would be less drag?

Happy New Year!

When the vessels are too heavy and break through the ice, then what? And what about locks?

Hmmm, wonder if ice was harvested from the canals back in the day.

We passed through a 13 Km tunnel towed by the very same chain driven tug depicted by your first illustration while cruising in our boat. It's purpose was to eliminate deisel fumes while travelling in the tunnel. Speed was about 3-4 Knts towing a train of several loaded barges besides our boat. The electric motor was surprisingly small. The chain made quite a racket passing over the sprocket which leads me to believe that there would a fair amouny of wear for this system. I believe that canals with towpaths would be very valuable to an energy constrained future. A very pleasant(if slow) way for a passenger to travel also.

Glad to see this posted to TOD after reading it elsewhere earlier. Thanks Gail.

OFF TOPIC

The network tv news reporters seem to have discovered the fact the economy is in trouble over the last couple of days.

Maybe they finally have a clue.

New York State was literally shaped by the Erie Canal. The cities of Buffalo, Rochester, Syracuse, Utica, Schenectady & Albany are all strung out along the Canal and drew much of their economic energy from it during the 19th Century. New York City became the dominant port on the East coast because of the connection to the Canal and the Great Lakes via the Hudson River.

Fortunately, the Erie Canal has been fairly well maintained by the State and is fully operational. Although there is practically no commercial traffic these days, there may well come a time in the not-too-distant future when canal barges once again help keep the New York economy moving.

The Canal is drained for the winter between November and May. I suppose that the schedule could be stretched by several weeks at either end, but the winter shutdown would certainly call for stockpiling of canal-borne commodities.

Certainly the idea of electrically-drawn barges would be easily adaptable to the Erie Canal. The old towpath has already been adapted into a series of heavily traveled bikeways all along the Canal route.

Allegheny Portage Railroad

http://en.wikipedia.org/wiki/Allegheny_Portage_Railroad

Built to connect Philadelphia & Pittsburgh via canal boats. The barges were broken into two pieces, mounted on a railroad car and then hauled up 5 inclines (1,399' on one side, 1,172' on the other side) and then down 5 more inclines to get over the Allegheny Mountain Divide.

It operated for 20 years.

Sorry, short on time today.

Best Hopes for Mature Technology,

Alan

PS: Well done article !

Why not just use mules.

Self replacing ( well with cross breeding )

Zero high technology needed. Where rail makes sense they can be used to pull rail cars for a unified system.

I guess I don't see the aversion to horse/mule transport its cheap in the sense that all inputs are local and the entire system requires on blacksmith level technology. In general its a fixed and finite solution that really does not need change.

Pastures etc for the mules could be developed along the way. In winter if the ice is thick enough then sleds could be used or you simply don't move much stuff over the winter and thats the way it is and always has been.

Now assuming a low population then one might not use anything but natural rivers for the most part if the population is low enough then why have any substantial population far from the sea or rivers or at best short canals and perhaps short rail roads.

That not to say you won't have any population away from these areas but their needs could easily be met with solar powered blimps with perhaps a few fast aircraft basically for emergencies.

Its hard for me to really consider what a society that enacted population control would do. I'd argue that if such a society existed it would simply populate the best places for humans which seems to be harbors and the navigable rivers. With very low densities beyond these.

Here is a list of large harbor cities.

http://en.wikipedia.org/wiki/Harbor#Natural_harbors

Add in the huge number of smaller harbors plus rivers and a population of a few hundred million is readily supported effectively doing nothing except living in the easiest places for humans to live.

I'm not sure exactly what the number would be and obviously global warming will change the places but it seems to me the first question is what is the population.

Now if we don't control our population aggressively then I think and attempt to move to renewables would probably fail fast. Its hard to see what would happen in the uncontrolled case again population determines the answer not available technical approaches.

I think at least for transport the technical solutions are not the problem the problem is whats the population density your trying to support and if your controlling it then why move much beyond natural solutions ?

"I've got a mule, and her name is Sal.

Fifteen miles on the Erie Canal."

It's certainly been done before.

Thats one that might make sense.

However for example the Suez canal has lead to a serious species invasion between the Red Sea and Med.

Thus if you look at it from that angle canals witch often link watersheds and allow for invasive species are not a good idea in a world of super eco-freaks.

Thus if your serious about reducing human impact and controlling population it seems to me that a lot of things we did in the past probably won't be done.

Canals where sort of the zenith or nadir technology of the horse age and generally created without sensitivity to the environmenal impact.

I'm to some extent arguing that we probably would swing entirely the other way with few exceptions i.e we minimize or impact and canals would be rare.

I don't think there is a middle ground where you potentially trash the environment in a renewable manner and control population etc.

Its one extreme or another. The future is either some sort of techno-megapolis where nuclear energy has been supplanted with fusion and cheap energy allows low grade ores and even seawater to be mined or its a few flower children communing with nature and using low impact technology with a preference for settling naturally best fit place for humans and keeping the population low enough to keep our niche well below its maximum carrying capacity.

Thus why not mules ?

If mules don't work and the canal impact is to large then simply don't do it shoot for a lower population level at least in the region.

If you aggressively control population its surprisingly how little has to be done to the environment.

I see no reason to throw technology away I'm confident that given some thought we could live very comfortable lives while having effectively no impact on the environment and there is a Universe to explore.

So its not a return to the stone age but a return to the population densities that allowed people to pretty much just hang out on earth while nature did its thing.

If we did such a thing then its hard to really understand what technology makes sense and what does not indeed I've increasingly come to the conclusion that in the end you effectively are not using technology but going through our knowledge base and taking it in a different direction. In fact the further down this path I go the more the way I think diverges from even current renewable advocates.

It actually leads to focusing on the problem of providing a comfortable living given the prime places to live. In one sense its not a hard problem but if you assume high tech you move towards a universal manufacturing solution thats done on a small scale. You build everything you can and trade become limited to luxury items and art and raw metals. Back to my techno future above its interesting that extraction from seawater might still fit. In this case only done in a few places using renwable energy but instead of mining a focus on water extraction of the essential minerals for a high tech society becomes a central problem. For the echo-freak biological solutions seem more likely, A simple example is seaweed which concentrates iodine. Now in many cases most of our current uses of rarer elements can be replaced with organic alternatives. No reason computers can be made of plastic eventually.

But you still need small amounts of elements such as platinum etc that simply are not readily replaceable.

Good chance that asteroid mining might become important along with sea water reclamation and excellent recycling.

Nanotech and associated concepts offer great promise in the creation of universal constructors needed to allow a distributed low impact high tech society.

Now outside of advanced medical care and super high tech advances it seems we may actually live more like cavemen in super deluxe caves if you will or stone zero energy homes that last for centuries and blend with the environment. In any case once you simply assume a very low population and don't think about how it got there then the problems that need solving are quite different.

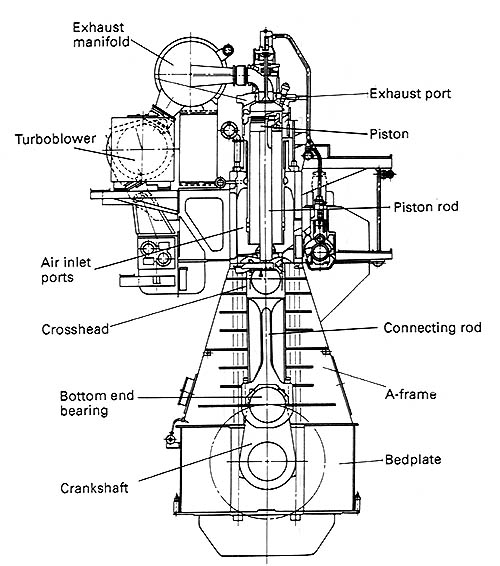

A 2-stroke diesel engine is not as efficient as a 4-stroke diesel engine. The reason is the exhaust and intake ports are located at the bottom of the cylinder. Granted sometimes there is an intake valve but still an exhaust port is needed. This limits the expansion of the hot gas. A 4-stroke engine the gas expands the full length of the stroke whereas a 2-stoke to a lesser extent.

As to mixing alcohol with diesel, diesel is injected into the cylinder in liquid form and alcohol needs to be vaporized before combustion can take place. Injectors will not inject a vapor. Also diesel fuel is needed in the cylinder to lubricate the upper part of the cylinder. Without lubrication in the upper part of the cylinder the engine will trash.

Waste heat is recovered in the turbo. The hot gas expands doing work on the compressor. The compressor in effect causes a 4-stoke engine to have two power stokes. The intake stroke is pressurized by the compressor as opposed to a naturally aspirated engine that uses energy to draw the air into the cylinder. The turbo causes the intake stroke to be a power stoke.

A 2-stroke diesel engine is not as efficient as a 4-stroke diesel engine.

Large 2-stroke diesel engines are actually more efficient.

http://people.bath.ac.uk/ccsshb/12cyl/

The reason is the exhaust and intake ports are located at the bottom of the cylinder. Granted sometimes there is an intake valve but still an exhaust port is needed.

The exhaust ports are located at the top of the cylinder and there are no intake valves but exhaust valves:

Waste heat is recovered in the turbo.

This is also the case with a 2-stroke diesel.

Also see p 323-325 of The Encyclopedia of the History of Technology re. marine compression ignition engines. Two-stroke single-acting engines of this type....(fuel consumption specs.) This performance makes engines of this this type the most efficient of all thermal prime movers.

The 2-stoke uniflow engine can leave the exhaust valve open for part of the compression stroke, causing unequal compression and expansion ratios; this reduces the compression work. The turbocharger (and intercooler, if used) can make up for the lost volumetric efficiency.

Did you think that diesel fuel does not need to vaporize before it can burn? Alcohol can be carbureted into a diesel's intake air, as the octane rating is high enough not to self-ignite. A pilot injection of oil starts the flame.

Diesel fuel should not get to the cylinder walls in normal operation; it should be confined to the bowl in the piston crown.

But with a much smaller BMEP, whereas in a 2-cycle, every downstroke is a full power stroke.

The efficiency advantage moves according to the refinements you implement. You get into complications when you start working with turbocompounding (where the 4-stroke's ability to run the exhaust manifold at higher pressure than the intake comes into play) but the largest engines cannot afford to waste downstrokes just to inhale.

No No. 2-stoke engines use a supercharger that is driven from the engine crank. The supercharger draws power from the engine and reduces its brake horsepower. The supercharger is necessary to scavenge the air from the cylinder on the exhaust stroke and to charge the air on the intake stroke. A turbo is using waste heat and adds to the efficiency.

A scavenger pump is not a supercharger. Superchargers supply compressed combustion air.

You are thinking about automotive style engines. the big marine diesels make full use of their waste heat, some of them employing a steam cycle from the exhaust to drive the ships electrical generators.

Even without a steam cycle, they are still more efficient than any other engine ever built (incl gas turbines)

http://people.bath.ac.uk/ccsshb/12cyl/

"The Wartsila-Sulzer RTA96-C turbocharged two-stroke diesel engine is the most powerful and most efficient prime-mover in the world today."

"Fuel consumption at maximum power is 0.278 lbs per hp per hour (Brake Specific Fuel Consumption). Fuel consumption at maximum economy is 0.260 lbs/hp/hour. At maximum economy the engine exceeds 50% thermal efficiency. That is, more than 50% of the energy in the fuel in converted to motion.

For comparison, most automotive and small aircraft engines have BSFC figures in the 0.40-0.60 lbs/hp/hr range and 25-30% thermal efficiency range."

In metric terms, that is 0.168kg fuel per kWh produced.

From the Deutz engines (a leading German manufacturer) US website, the TD2015 V6, a turbocharged 4 stroke diesel, gets 208g/kWh, and most of their other engines are 210 to 230 g/kWh. This is in the order of 40% thermal efficiency, which is still very good.

All the large marine engines are two stroke, and they are all highly efficient. It is mainly their size that makes them so efficient but it is impractical to build 4 strokes at this size. Four strokes may be more efficient at 100's of kW, but into the 10,000's kW the two strokes reign supreme.

Now, for barge engines, you wouldn't be using this size, you would be back into 100's of kW (barge tugs are typically 300-800 kW) and at this size, the market is dominated by four strokes.

GE's H System* power island (H System) is an advanced combined cycle system capable of breaking the 60 percent efficiency barrier integrating the gas turbine, steam turbine, generator and heat recovery steam generator into a seamless system.

http://www.gepower.com/prod_serv/products/gas_turbines_cc/en/h_system/in...

This is natural gas > electricity not motion (in many cases electricity is more desirable, even on board ships).

Hydroelectric generators are @ 98% efficiency. Turn them into motors and NG > motion is 58.8%. Realistically, 58% is doable.

Low quality bunker fuel does not burn as well as NG (UNDERSTATEMENT) but it would be interesting to see if combined cycle technology could be adapted to marine propulsion. First use on an LNG supertanker, burning the boil-off on one leg (perhaps saving enough LNG for the return voyage).

Alan

Alan, it's not quite that simple. The military does use gas turbines on destroyers and cruisers, and often use steam injection (part way between simple and combined cycle) to improve output. To use a combined cycle turbine + generator + motor in a large cargo ship would take up lots of space. They stay with the large diesel as they need massive torque and 100 rpm on the prop shaft, but also they run at reduced load while maintaining efficiency - turbines are quite inefficient at part load. The LNG tankers already use their boil off gas as fuel for the diesels, they introduce it in the air intake, called "fumigating", engine can run up to 90% NG, with the diesel injection serving as the pilot ignition. Many industrial NG engines are actually diesels set up like this.

Ships may start using LNG because it is cheaper than bunker fuel, but it takes up 70% more space, and requires pressure containers, so you can't have odd shaped fuel tanks - this chews up valuable cargo space. And, of course, LNG is not available other than at LNG ports.

We are a little off topic here, but you can rest assured that ocean marine propulsion is already at a very high level of efficiency.

I agree and its been posted many times yours was a excellent post.

I think that if our current shipping does go it will be because of the following issues.

Sort of in the order the dominoes might fall.

1.) Drop in international trade less demand for the large ships.

2.) Massive overcapacity and huge losses.

3.) Spiraling bunker fuel prices.

4.) Crippling shortages.

5.) Rampant piracy.

6.) Out right war zones and sinkings.

7.) Rapid drop in maintenance ( tramp steamers)

Finally at this point smaller ships don't provide the economies of scale and there simply is not the trade to support the larger ships.

The crippling event in my opinion will be when we see serious bunker shortages esp at major ports as that will send shock waves through and already seriously weakened shipping industry.

Near the end more and more ships will simply be run into the ground skimping heavily on maintenance these ships will of course out compete anyone trying to actually maintain their equipment. Bunker shortages make timing so volatile that additional repair problems don't add much to the chaos.

Of course accidents will happen in this sort of situation.

So overall just a sort of decay if you will. I think many of these symptoms are starting to pop up i.e everything I've mentioned is in my opinion already started so its in general just and extrapolation out into the future.

Whats interesting is I also don't see any replacements really no rapid move to sail etc just basically rusting away and deterioration over time. A return to sail or other resurgence is probably decades away after the fleet my understanding is and average ship tends to last for about 30 years so this could go for a long time sort of dwindling away.

I was aware that LNG tankers used the boil-off, but not that they needed 10% oil mixed in.

There are weight vs. space issues. I could well believe that a combined cycle plant takes more space than a marine diesel. I am less certain that it takes more weight (if adapted for marine use). Marine diesels have a lot of steel.

As noted, a super-tanker sized LNG carrier might be a viable option for combined cycle operation. Power plant sized for typical speeds so it operates very close to full load (perhaps auxiliary diesels for extra speed or breakdown of main powerplant).

Combined cycle can run on 100% NG, so run with cargo on boil-off and discharge, say, 96% of cargo at port and use remainder to return in ballast. No oil required and no modification of ship structure except smaller oil tanks and larger powerplant. (Since this is electric final drive, some PV panels might provide auxiliary power when available).

The main obstacle I see is the engineering costs for a novel powerplant with a very small initial market.

And yes, marine propulsion has been driven by economics towards a high state of efficiency.

Alan

Alan,

You can actually replace the fuel injection with a spark plug, but then your engine is NG only. Keep the diesel system, and you then can run at any proportion from 10 to 100% oil, and I I was a ship owner, for anything other than an LNG tanker, I'd keep the fuel injection, and I bet even the LNG ships still do. If we are thinking of these things, I'm sure the LNG shipbuilders are - they are all purpose built, not conversions.

I expect the combined cycle turbine would be lighter than the diesel, but I think volume is the real issue. The generator and motor are your "gearboxes", but these too take up volume, though the turbine/generator can be placed away from the motor.

Memmel, there's one factor I think you missed in your domino series, and that's coal. You will see a return to coal for ship propulsion long before you see sail (as anything other than auxiliary power anyway). I read somewhere about some new cargo ships being built that were going to be coal fired steam. If I was in the coal shipping business, that's the way I would be going today. But if bunker fuel got as expensive as you think, I would expect to see some ships start to use coal gasification to run their diesel engines, with the fuel pilot ignition same as NG. Sure it's a pain, and would take up space, but when coal, on an energy basis, is the equivalent of $10-15 barrel oil, that's a powerful incentive to switch fuels.

Also, the new superships are much more efficient for fuel used per ton mile, so, leaving coal gasification aside, I expect they would be the last ones floating, and they are also the newest and best maintained. The tramp ships, regardless of how they skimp on maintenance, would quickly find their fuel cost per ton-mile is more than the total operating cost for the superships, at least for transoceanic voyages.

bringing this back to the original barge article, my take on it is that the barges still need to be large scale, to compete with rail. That means rivers, not local canals. The local canals may still be useful, especially if they serve places not connected already rail. They DO have one advantage over rail, and that is that anyone with a barge can use them, so it's better for small/local business. But I would consider them the transport equivalent of solar PV's - great localised solutions, especially for off grid, but they will always remain a tiny portion of the overall market.